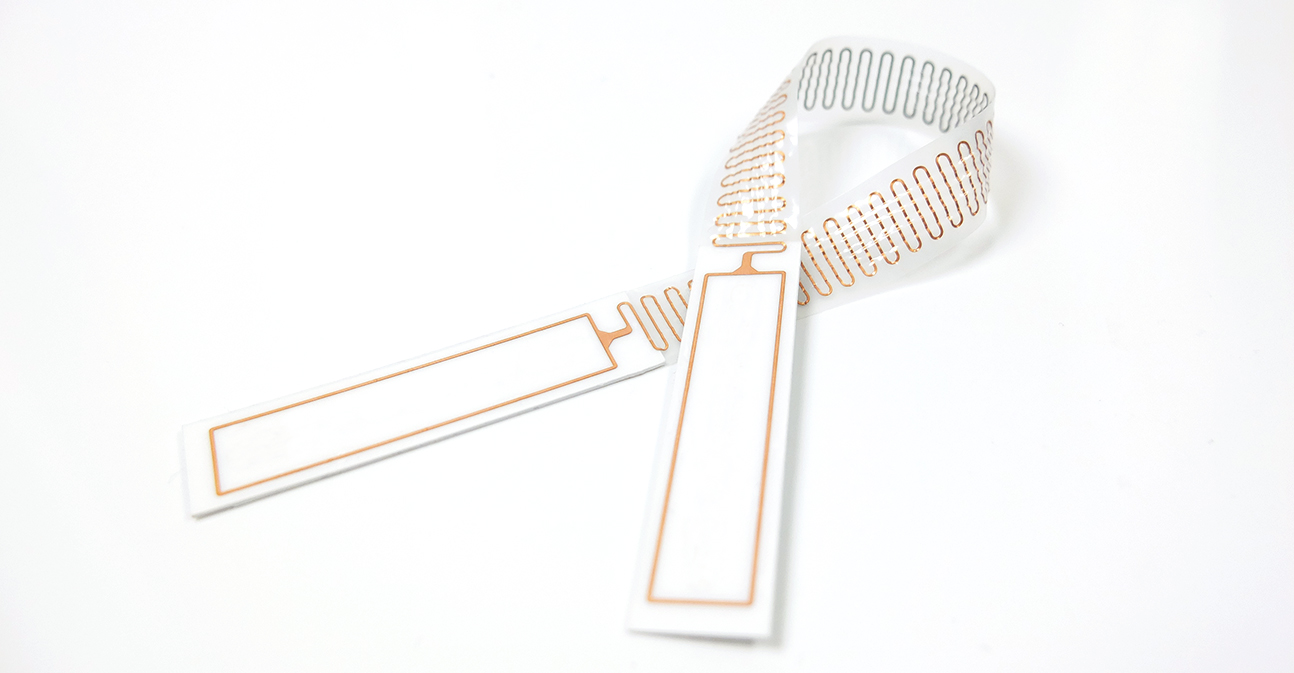

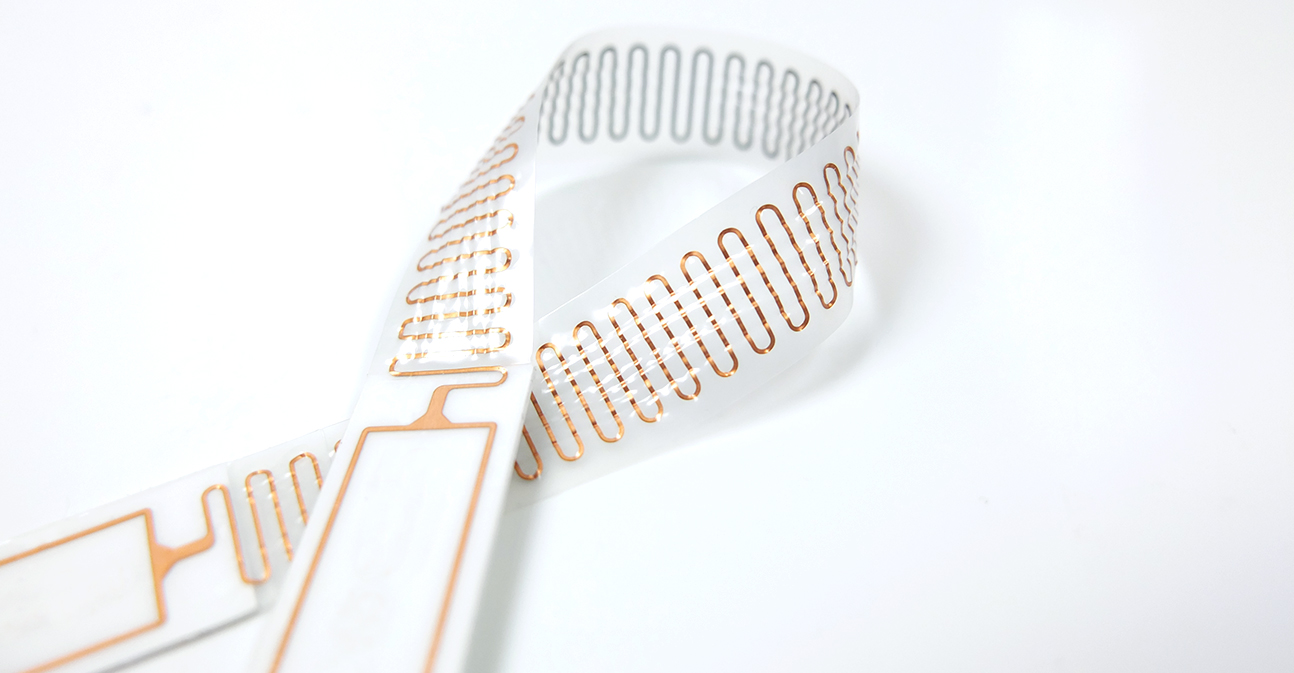

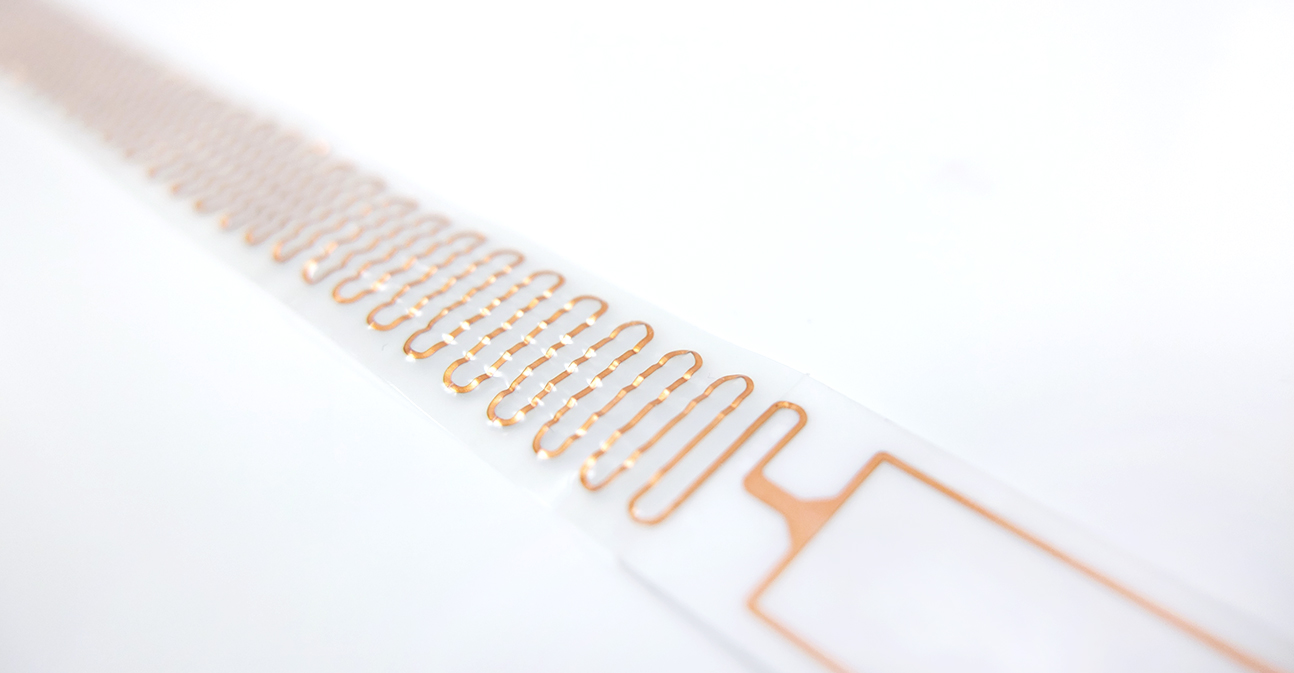

Transparent flexible printed circuits

Thanks to the numerous advantages that flex and flex-rigid printed circuit boards offer (e.g. cost, space and weight savings) they are increasingly being used in a wide variety of devices. The transparent printed circuit board is another innovative variant of the flexible printed circuit board.

By using polyimide as base material, the system is very flexible and the substrate is only a few microns thin.

In the automotive industry, flexible circuits are used in instrument panels, underbody controls, circuits hidden in the headliner of the cabin, and in ABS systems. In computer peripherals, flexible circuits are used on the moving printhead of printers to connect signals to the moving arm carrying the read/write heads of hard disk drives. Consumer electronics devices use flexible circuits for example in cameras, mobile phones, calculators or training monitors. Flexible circuits can also be found in industrial and medical devices and wherever many connections are required in a compact housing.

You would like to have your flexible or rigid-flexible printed circuit board assembled? No problem - this is possible at any time! We offer PCB assembly in small series or you can take advantage of our fast prototype assembly. Have a look at our PCB ASSEMBLY site and contact us!

Technical specifications:

- 1-2 layer transparent polyimide FPC, surface ENIG

- max. size: 15 mm to 450 mm

- max. thickness: 0.45 ± 0.1 mm

- min. thickness: 0.2 ~ 0.185 ± 0.03 mm

- copper foil: 2-12 µm

- min. hole: 0.3 mm

- min. line width: 0.15 mm

- min. line spacing: 0.15 mm

- immersion gold thickness: Ni: 1 ~ 6 µm, Au: 0.05 ~ 0.1 µm

- transparency: 88 %

- heatresistance for soldering: 260 °C x 5 sec.

- adhesive strength: 490 N/m

- glass transition temperature: 300 °C

- operating temperature: -25 °C to +75°C

The flexible silicone printed circuit board – a trend-setting technology

Together with our manufacturers, we are continuously working on new future-oriented technologies – such as this silicone printed circuit board study. Which is characterized by its extensibility compared with conventional substrates. Furthermore silicone is a high-quality material that can withstand extreme mechanical demands, has a high degree of purity for clinical applications and it is particularly kind to the skin.